The Craftsman LT2000 drive belt diagram provides key information about the belt and its operation. Keeping your lawn mower’s belt in good condition is vital for top performance. This diagram also helps you determine when to replace the belt.

Your lawn mower belt drives the blades, providing a precise cut. A strong, dependable belt is key to a beautiful lawn. A damaged or failing belt will certainly disrupt your lawn maintenance.

Changing drive belts on most lawn tractors is generally easy. You’ll likely need a wrench, a screwdriver, and a fresh belt. The replacement is usually fast and simple, often done in minutes. If you’re unsure about doing it yourself, consider getting help from a qualified technician.

Let’s dive into the Craftsman LT2000 drive belt diagram. We’ll explore its purpose, how to replace it, why it’s important, and other vital details. This information is updated for 2025.

Dive into the fascinating realm of dippers as we journey through 2025!

The Craftsman LT2000 Drive Belt Diagram

In 2025, the Craftsman LT2000 is still a popular pick for easy and reliable lawn maintenance. A frequent problem is the drive belt. This belt can degrade with use. Replacing it quickly is key to maintaining your mower’s performance.

We will present all topics in order. We’ll start with the drive-belt demonstration.

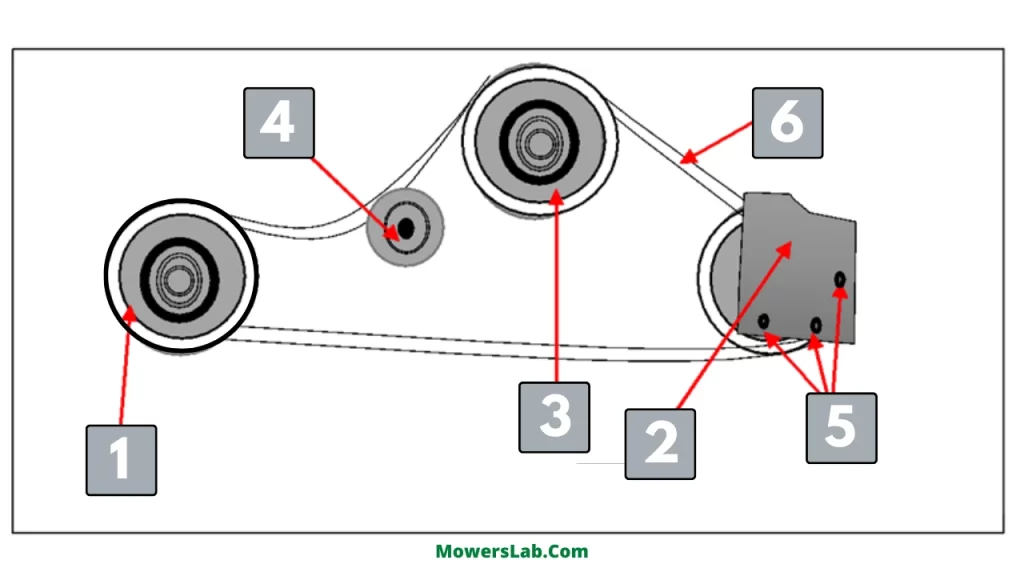

Get in-depth details on each numbered part of the Craftsman LT2000 drive belt diagram, shown earlier.

| Moving Parts | How does It work? |

|---|---|

| Left Hand Double Pulley | Move heavy loads with less effort |

| Right Hand Double Pulley | Move heavy loads with less effort |

| Center Pulley | Help to hold drive belt |

| Deck Idler Pulley | Maintaining tension on the drive belt |

| Self-Tapping Screw Assembly | Types of fasteners |

| Deck Belt | It connects the engine |

Left Hand Double Pulley

Employing a dual pulley setup on the left dramatically cuts down the force required for lifting. This enhanced mechanical leverage simplifies the movement of weighty items.

This happens because pulling twice dramatically increases the leverage.

Right Hand Double Pulley

The right-side double pulley on the lawn mower mirrors the left pulley’s job. It sits on the mower’s right side.

Center Pulley

This is the main drive belt pulley designed for the Craftsman LT2000 lawn tractor. This grooved wheel, also called a sheave, holds ropes, wires, or belts securely. It provides essential guidance and support for moving parts.

Pulleys offer amazing adaptability. They appear in numerous machines and tools we use daily.

Deck Idler Pulley

The deck idler pulley maintains optimal drive belt tension. It also directs the belt’s path around the engine. Correct belt tension ensures efficient engine power delivery.

Too much belt slack can cause slippage. This can lead to engine overheating or the belt coming off the pulleys. The idler pulley is key for correct belt alignment. It stops the belt from rubbing against other engine parts.

Self-Tapping Screw Assembly

Self-drilling screws provide a simple and effective fastening method. They eliminate the need for pre-drilling, creating their own hole when driven into metal, plastic, or wood.

These are self-tapping screws, engineered to create their own threads as they’re inserted. This innovative feature makes them ideal for various applications. Think metal fabrication, plastic assembly, and woodworking projects – they excel in all!

Deck Belt

Your riding lawn mower relies heavily on the mower deck belt. This belt transmits power from the engine to the blades, enabling them to cut. A good belt guarantees efficient mowing. A damaged or worn belt can cause the engine to overheat or the blades to become misaligned. In extreme situations, it could even result in engine breakdown.

Keep your deck belt in top condition for optimal performance. Replace worn belts promptly. A new deck belt is vital for all riding mowers. This simple step ensures your mower runs safely and efficiently, saving you money in the long run.

Craftsman LT2000 Drive Belt Size

Maximize your Craftsman LT2000 riding mower’s performance with the Rinlius 144959 deck belt. This belt is specifically designed for the LT2000 model. It measures 1/2 inch in width and 95 inches in length. Expect smooth and efficient mower deck operation with this belt.

Boost your lawn mower’s efficiency with the Rinlius 144959 Deck Belt. The right size guarantees peak performance for all your 2025 lawn maintenance tasks.

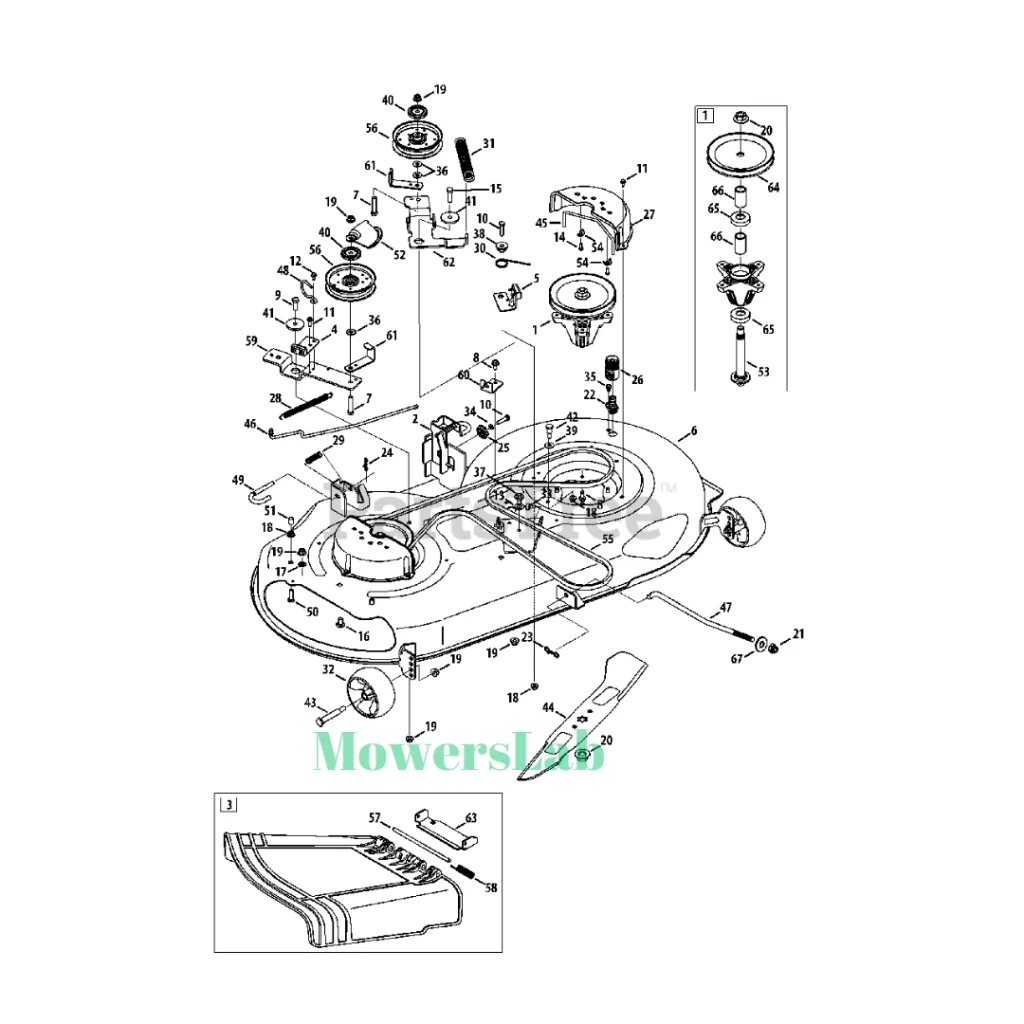

Explore a detailed visual guide to this mower deck! Updated for 2025, see every component clearly.

Craftsman LT2000 Drive Belt Working Mechanism

Your Craftsman LT2000 lawn mower relies heavily on the drive belt. It’s crucial for transferring power to the engine, blades, and wheels. The belt also converts engine power into rotational force. This force spins the blades at high speed, giving you a clean, even cut.

Torque is crucial for engine power. Consistent performance, such as daily driving, can be used to power equipment like lawnmower blades or boat propellers.

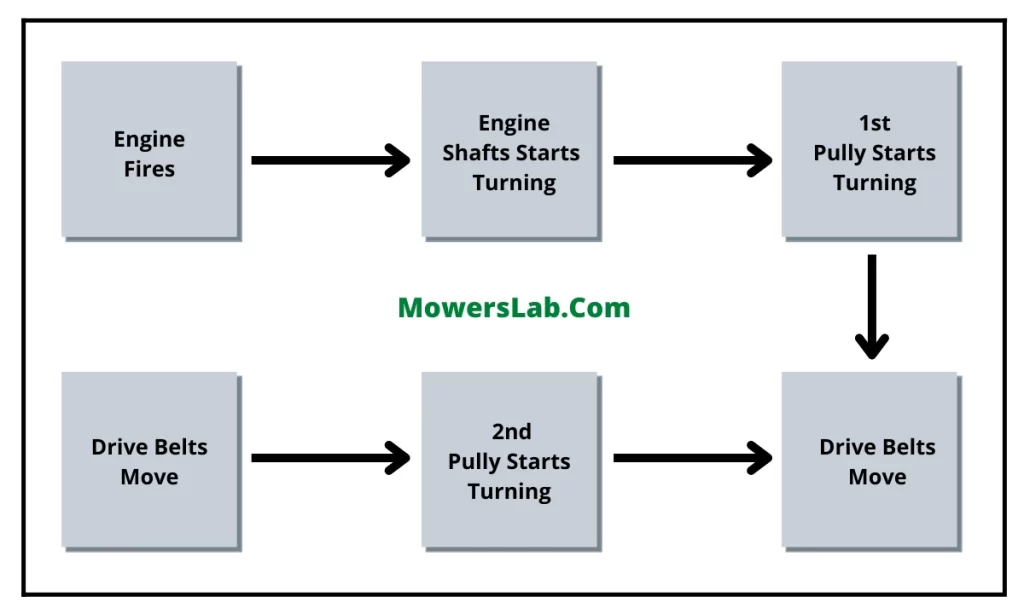

How Can Craftsman LT2000 Drive Belt Transfer Power?

Craftsman LT2000 owners often ask about the drive belt’s function. Some incorrectly think it’s just for show. Actually, the drive belt is essential. It effectively moves power from the engine. This power then turns the wheels.

The 2025 Craftsman LT2000 utilizes a drive belt connecting the engine to the transmission. The engine’s rotation drives this belt. Consequently, the transmission spins, transferring power. This power transfer allows the mower’s wheels to move, ensuring efficient operation.

Grasping this procedure is vital for maintaining your Craftsman LT2000’s optimal performance in 2025.

Initially, the primary pulley sets the drive belt in motion. Next, the drive belt powers the secondary pulley. This pulley connects directly to the input shaft. Its movement then drives the transmission shaft.

Essentially, the pattern concludes here. Therefore, the complete movement sequence ends.

Here’s a Demonstration of What Happens on Craftsman Lt2000 Drive Belt

The 2025 model boasts a redesigned power system. A direct power line now fuels the blade drive wheels. This allows the blades to move in a circular, oscillating manner. This innovative motion mimics a traditional engine’s drive belt. The result is efficient, back-and-forth movement, ensuring exceptional cutting performance.

How to Replace Craftsman Lt2000 Drive Belt?

Replacing your Craftsman LT2000’s drive belt is now easier than ever! This updated 2025 guide simplifies the process. Even with minimal tools and experience, you can handle this repair. A broken or worn belt shouldn’t keep you from mowing. Follow these clear steps to get your mower running smoothly again, quickly.

How to Remove Craftsman Lt2000 Drive Belt

How To Remove Craftsman LT2000 Drive Belt

In 2025, replacing your Craftsman LT2000 drive belt is easier than ever! Use this straightforward, updated guide for a smooth and successful replacement.

How to Install Craftsman LT2000 Drive Belt

Replace your Craftsman LT2000 mower’s drive belt effortlessly! Use these straightforward instructions for optimal performance.

FAQ

What Is the Craftsman Lt2000 Drive Belt Size?

The Craftsman LT2000 drive belt size is 1/2 x 95.5 inches. This is the size you will need to properly install the drive belt on your craftsman lt2000. Be sure to measure your current belt before ordering a new one to ensure you get the right size. Having the wrong size can lead to installation problems and decreased performance from your lawn tractor.

How Long Is the Drive Belt on A Craftsman Riding Mower?

The drive belt on a craftsman riding mower can be anywhere from 42 to 50 inches long, depending on the model. The primary belt is usually shorter than the secondary belt, and both belts are typically made of durable rubber or plastic.

If either of your belts fails, it’s important to replace them both at the same time to ensure optimal performance. You can find replacement belts at most home improvement stores or online.

Can You Adjust the Drive Belt on A Craftsman Lawn Mower?

No, then there s no need for adjustments. The manufacturer instead recommends simply replacing the belt if it becomes worn or damaged. It is not possible to adjust the blade drive belt on these machines.

Why Does My Drive Belt Keep Coming Off My Riding Mower?

There can be many reasons why a drive belt comes off a riding mower. However, in common scenes, it is due to the bearings of pulley or spindle housings, belt keepers, and brackets. If these components are not functioning properly, it can cause the belt to slip off. It is important to inspect these parts regularly and maintain them so that they are in good condition.

How Long Should a Mower Drive Belt Last?

Mower drive belts typically last between 3 and 4 years with regular use. However, this lifespan can be shortened if the belt is subjected to wet conditions or heavy loads. Additionally, if the belt is not properly tensioned it can wear out more quickly.

Warping Up

The Craftsman LT2000 drive belt diagram offers a clear visual guide to the drive belt system. It highlights each component and its function. This updated illustration includes a numbered parts list with detailed descriptions. It also presents the complete mechanism and answers common questions about the drive belt system, providing users with a complete understanding in 2025.

We hope this information fully addressed your question. Need more help? Consult an expert. Provide complete details about your issue for the best support.

This issue appears more intricate than first anticipated. Immediate machine maintenance is now essential.

Stay tuned for our next update, packed with even more engaging content!

Discover Further: